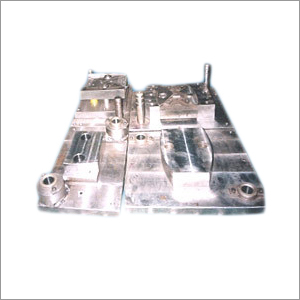

Blanking Shearing Dies

Product Details:

- Tolerance 0.01 mm

- Life Span Approximately 300,000 to 1,000,000 cycles

- Mould Base Mild Steel or Standard Tool Base

- Core Material High Speed Steel / Carbide

- Working Process Blanking, Shearing, Punching

- Material High Grade Alloy Steel

- Shaping Mode Press Mould

- Click to view more

X

Blanking Shearing Dies Price And Quantity

- 1 Piece

- Rectangular, Circular, Customized

- CNC Machined, EDM, Grinding

- HRC 58-62

- Easy to Maintain and Replace

- Smooth Finish

- Metallic Grey

- High Strength, Wear Resistant, Rust Proof

- Polished/Heat-treated

- Automotive, Electrical, Sheet Metal Industries

Blanking Shearing Dies Product Specifications

- High Speed Steel / Carbide

- Precision Ground Steel

- Press Mould

- Blanking, Shearing, Punching

- High Grade Alloy Steel

- Mild Steel or Standard Tool Base

- Approximately 300,000 to 1,000,000 cycles

- 0.01 mm

- Interchangeable Hardened Tool Steel

- Rectangular, Circular, Customized

- CNC Machined, EDM, Grinding

- HRC 58-62

- Easy to Maintain and Replace

- Smooth Finish

- Metallic Grey

- High Strength, Wear Resistant, Rust Proof

- Polished/Heat-treated

- Automotive, Electrical, Sheet Metal Industries

Blanking Shearing Dies Trade Information

- Telegraphic Transfer (T/T)

- Wooden and plastic packaging

- All India

Product Description

In line with customers variegated requirements, we bring forth an impeccable range of Blanking And Shearing Dies. The given die is manufactured and fabricated under the guidance of our deft technocrats with the aid of advance techniques using supreme quality steel. This is extensively used in automotive industry for manufacturing different auto parts. Due to its unique temper resistance properties and excellent thermal conductivity, this shearing die can easily eliminate heat and lowers the possibilities of heat cracks and soldering effect. Also, offered Blanking And Shearing Dies can be bought by our clients at marginal prices.

High Performance for Demanding Industries

These dies are specifically designed for the automotive, electrical, and sheet metal sectors, where durability and accuracy are critical. By employing premium core materials such as high-speed steel or carbide, the dies maintain superior sharpness and edge integrity through extensive production runs.

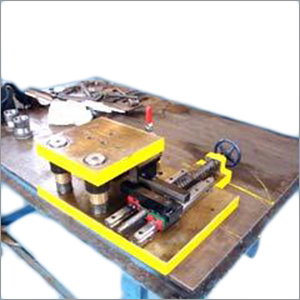

Precision Manufacturing Methods

Fabricated using advanced CNC machining, EDM, and precision grinding, each die offers exceptional dimensional accuracy and consistency. The smooth, metallic grey finish and customizable shapes ensure seamless integration into modern press mould systems, supporting a wide range of industrial applications.

FAQs of Blanking Shearing Dies:

Q: How are Blanking Shearing Dies maintained, and how easy is it to replace them?

A: These dies are designed for straightforward maintenance and replacement. Their modular construction with interchangeable punch dies enables quick swaps, reducing downtime. Routine cleaning and proper lubrication further extend their operational life.Q: What manufacturing processes are used to produce these dies?

A: Production involves CNC machining, EDM, and high-precision grinding to achieve tight tolerances and a smooth surface finish. These processes ensure each die meets strict industry requirements for accuracy and performance.Q: When should these dies be used in industrial applications?

A: They are ideal for high-volume operations in automotive, electrical, and sheet metal industries where precision blanking, shearing, or punching of sheet materials is required.Q: Where can I source these dies?

A: You can procure these precision dies from leading manufacturers and suppliers based in India who specialize in high-strength, wear-resistant tooling for industrial applications.Q: What are the primary benefits of using dies with a surface coating and hardened finish?

A: Surface coating and heat treatment confer enhanced wear and rust resistance, increased toughness, and a smoother finish, resulting in longer service life and reduced maintenance intervals.Q: How long is the operational lifespan of these dies?

A: With recommended usage and proper care, these dies typically last between 300,000 and 1,000,000 cycles, depending on application intensity and maintenance practices.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email