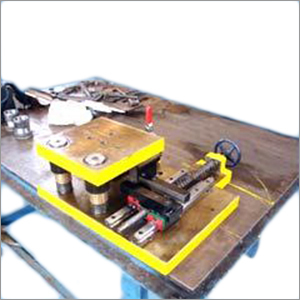

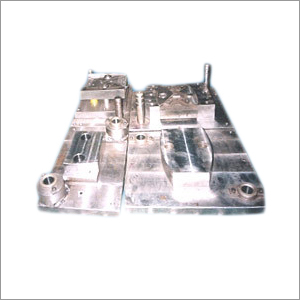

Forming Dies

Product Details:

- Tolerance 0.01 mm

- Life Span Up to 500,000 cycles

- Mould Base High-quality Hardened Steel

- Core Material Alloy Tool Steel

- Working Process Cold/Forming

- Material High Grade Steel

- Shaping Mode Cold Forming

- Click to view more

X

Forming Dies Price And Quantity

- 1 Piece

- CAD/CAM Supported

- Polished and Nitrided

- Vacuum/Induction Hardened

- Single/Multiple as Required

- HRC 58-62

- Protective Box/Crate Packaging

- 10 mm to 100 mm

- Available as per drawing

- Automotive, Electrical, Fastener Manufacturing

- 1000 Pieces/Month

Forming Dies Product Specifications

- Cold Forming

- 0.01 mm

- High Grade Steel

- Precision Ground Die Head

- Up to 500,000 cycles

- Custom Hardened Punch Dies

- High-quality Hardened Steel

- Alloy Tool Steel

- Cold/Forming

- CAD/CAM Supported

- Polished and Nitrided

- Vacuum/Induction Hardened

- Single/Multiple as Required

- HRC 58-62

- Protective Box/Crate Packaging

- 10 mm to 100 mm

- Available as per drawing

- Automotive, Electrical, Fastener Manufacturing

- 1000 Pieces/Month

Forming Dies Trade Information

- Telegraphic Transfer (T/T)

- Wooden and plastic packaging

- All India

Product Description

We feel immensely pleased to offer an excellent range of Forming Dies. Our given range is mainly demanded in fastener industry for shaping or cutting purpose by cold pressing. Free from all defects, the offered products are widely used in various engineering, automobile and automotive industries. This is known in the market for their superior performance. In addition to this, clients can easily avail these Forming Dies in multiple shapes, sizes and dimensions at minimum market rates and given time frames.

Precision and Longevity in Forming Dies

Our forming dies feature precision ground die heads and custom hardened punch dies, designed to deliver exact shaping and extended tool life in high-production environments. The use of vacuum or induction hardening strengthens the dies performance while high-quality mould base steels enhance overall stability, even under continuous operation.

Tailored Solutions for Multiple Industries

Recognizing the varied needs of the automotive, electrical, and fastener sectors, we offer customizable single or multiple cavity dies based on client specifications. Leveraging CAD/CAM software, we ensure that every product aligns precisely with your technical drawings and production requirements.

Quality Assurance at Every Step

Stringent quality checks, surface finishes such as polishing and nitriding, and accurate production tolerances guarantee top-notch dies. Our commitment to excellence is reflected in robust packaging and efficient manufacturing processes, ensuring reliability from order to delivery.

FAQs of Forming Dies:

Q: How are the forming dies customized to fit specific manufacturing requirements?

A: We customize forming dies based on clients technical drawings using CAD/CAM design tools. Customization covers cavity numbers, sizes (10 mm to 100 mm), and die features, ensuring each die suits your application in automotive, electrical, or fastener production.Q: What surface treatments are applied to enhance die durability and performance?

A: The dies receive a polished and nitrided surface finish, combined with vacuum or induction hardening. These treatments boost wear resistance, ensure high hardness (HRC 58-62), and extend tool life up to 500,000 cycles under demanding forming conditions.Q: When should I consider single or multiple cavity dies for my production process?

A: Single cavity dies are ideal for smaller batches or complex shapes, whereas multiple cavity dies increase output for high-volume manufacturing. We recommend selecting cavity number based on your specific production volume and part design needs.Q: Where are these forming dies produced and supplied from?

A: All dies are manufactured and supplied by our facility based in India, utilizing advanced CNC machining, quality control procedures, and protective packaging for global shipment.Q: What is the working process these dies are suitable for?

A: Our dies are specifically engineered for cold forming processes, which provide precision shaping and efficient metal forming, supporting various applications in fastener, electrical, and automotive manufacturing.Q: How does the precise tolerance benefit my manufacturing output?

A: Each die is manufactured to a strict 0.01 mm tolerance, ensuring consistent part accuracy, minimization of rework, and improved assembly fit, contributing to better overall productivity and reduced waste.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email