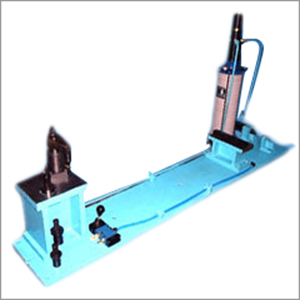

Load Holding Fixture

Product Details:

- Working Process Manual, Hydraulic, or Pneumatic Operation

- Die Head Precision Steel Die Head Included

- Life Span Approx. 5 Years under Normal Use

- Shaping Mode Load Holding and Securing

- Material High Grade Alloy Steel

- Application Industrial Load Testing and Holding

- Hardness 60-65 HRC

- Click to view more

X

Load Holding Fixture Price And Quantity

- 1 Piece

- 600 x 400 x 320 mm

- Bench/Structure Mounted

- Approx. 80 kg

- Overload Protection

- Rust-Resistant Coating

- Up to 25 Tons

- -10°C to 80°C

- Screw or Hydraulic Lock

Load Holding Fixture Product Specifications

- 0.02 mm

- Manual, Hydraulic, or Pneumatic Operation

- Precision Steel Die Head Included

- Load Holding and Securing

- 60-65 HRC

- Industrial Load Testing and Holding

- Approx. 5 Years under Normal Use

- High Grade Alloy Steel

- 600 x 400 x 320 mm

- Bench/Structure Mounted

- Approx. 80 kg

- Overload Protection

- Rust-Resistant Coating

- Up to 25 Tons

- -10°C to 80°C

- Screw or Hydraulic Lock

Load Holding Fixture Trade Information

- Telegraphic Transfer (T/T)

- Wooden and plastic packaging

- All India

Product Description

Facilitated by advanced machinery and contemporary technology, we are offering a qualitative assortment of Load Holding Fixture for regulating furnace process. Used for holding and keeping various types of machines fixtures, these products find usage in the electrical industry. The offered products are known in the industry for their less space consumption, longer service life, non-corrosive surface and sturdiness. Load Holding Fixture is packed in special packaging material so as to ensure their safe and secure delivery.

Precision and Reliability for Heavy Duty Applications

Engineered to endure rigorous industrial demands, this load holding fixture ensures superior accuracy and safety for heavy load testing. With high-grade alloy steel construction and advanced clamping options, it provides steadfast load securing, making it indispensable in manufacturing, production, and testing environments.

Versatility in Operation and Mounting

The fixture supports multiple clamping mechanismsmanual screw or hydraulic lockand can be mounted on benches or structural frameworks. Its adaptable design and included precision steel die head allow for easy integration into varied industrial setups, catering to diverse load holding and testing requirements.

FAQs of Load Holding Fixture:

Q: How is the load holding fixture installed and where can it be mounted?

A: The fixture is designed for bench or structure mounting. Installation involves securing it to a stable surface using appropriate mounting bolts, ensuring firm attachment and optimal performance in industrial environments.Q: What types of operations are supported by this fixture?

A: The fixture accommodates manual, hydraulic, or pneumatic operations, providing flexibility for various industrial processes that require load testing or secure holding.Q: When should the overload protection feature be utilized?

A: Overload protection activates when the applied load exceeds the fixtures rated 25-ton capacity, ensuring both user safety and product integrity during operation.Q: What maintenance procedures are recommended for prolonging the fixtures lifespan?

A: Routine inspection for wear, regular lubrication of moving parts, and checking the rust-resistant coating help maintain its integrity, supporting a lifespan of up to 5 years under standard industrial usage.Q: How does the screw or hydraulic locking mechanism benefit users?

A: Both screw and hydraulic locks offer secure and adjustable clamping for various load shapes and sizes, enhancing operational efficiency and accuracy during tests or holding processes.Q: Which industries commonly utilize this load holding fixture in India?

A: Industries involved in heavy machinery production, metalworking, automotive parts testing, and component manufacturing frequently use this fixture for load holding and secure testing operations.Q: What materials and design details contribute to the fixtures durability?

A: High-grade alloy steel construction, precision steel die head, rust-resistant coating, and a design tolerating temperatures from -10C to 80C ensure exceptional durability and reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email