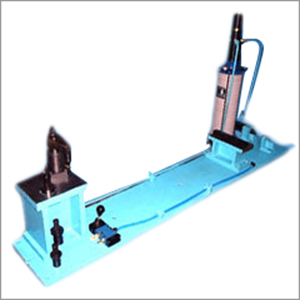

Spot Welding Fixtures

Product Details:

- Working Process Electric Resistance Spot Welding

- Life Span Up to 5 Years (Depending on Usage)

- Die Head Single/Multiple Die Head Available

- Shaping Mode Custom Fabricated Fixture

- Material High Grade Mild Steel (MS) / Alloy Steel

- Application Automotive Parts Assembly, Sheet Metal Fabrication, Industrial Welding Automation

- Hardness Up to 58-62 HRC (as per requirement)

- Click to view more

X

Spot Welding Fixtures Price And Quantity

- 1 Piece

- Compatible with Standard Spot Welding Guns

- Up to 500 kg

- <10 Seconds per Operation

- Low, with Replaceable Wear Parts

- Size, Shape, and Clamping as per Customer Drawing

- 10 kg to 75 kg (Depending on Design)

- Applicable for 230V/415V Welding Machines

- Base Plate / Modular Mounting

- Manual / Pneumatic / Hydraulic Clamping Options

- Anti-Corrosion Coated, Chemical Blackening or Zinc Plated Finish

- 0.05 mm

Spot Welding Fixtures Product Specifications

- Automotive Parts Assembly, Sheet Metal Fabrication, Industrial Welding Automation

- Up to 58-62 HRC (as per requirement)

- Custom Fabricated Fixture

- Up to 5 Years (Depending on Usage)

- Single/Multiple Die Head Available

- 0.02 mm

- High Grade Mild Steel (MS) / Alloy Steel

- Electric Resistance Spot Welding

- Compatible with Standard Spot Welding Guns

- Up to 500 kg

- <10 Seconds per Operation

- Low, with Replaceable Wear Parts

- Size, Shape, and Clamping as per Customer Drawing

- 10 kg to 75 kg (Depending on Design)

- Applicable for 230V/415V Welding Machines

- Base Plate / Modular Mounting

- Manual / Pneumatic / Hydraulic Clamping Options

- Anti-Corrosion Coated, Chemical Blackening or Zinc Plated Finish

- 0.05 mm

Spot Welding Fixtures Trade Information

- Telegraphic Transfer (T/T)

- Wooden and plastic packaging

- All India

Product Description

We are a fast growing company with impressive track record, engaged in providing a complete assortment of Spot Welding Fixtures. These products are used during welding work as these easily settle the joints and maintain the correct fit-up. The given fixture has accurate dimensions and is extensively used in the installation of welding machine. Available in numerous dimensions, these Spot Welding Fixtures are offered as per the required needs of the clients at a competitive price range.

Versatile Mounting & Finish Options

Choose from base plate or modular mounting to suit your setup, with anti-corrosion, chemical blackening, or zinc-plated finishes ensuring long-term durability, even in challenging industrial environments.

Precise Customization Capabilities

Every fixture is custom-fabricated to meet exact client requirements, encompassing size, shape, clamping options, and even hardness levels. Tolerances as tight as 0.02 mm guarantee accurate results for complex assemblies.

Reliable, Efficient, and Low Maintenance

Designed for cycle times under 10 seconds, our fixtures offer quick, repeatable operations, ideal for high-volume production. Replaceable wear parts and a robust construction help ensure a lengthy service life with predictable upkeep.

FAQs of Spot Welding Fixtures:

Q: How do Spot Welding Fixtures improve the speed and accuracy of welding operations?

A: Spot Welding Fixtures securely position components, enabling rapid and precise electric resistance spot welding. With a cycle time under 10 seconds per operation and surface flatness of 0.05 mm, they help ensure repeatable, high-quality welds.Q: What customization options are available for your Spot Welding Fixtures?

A: These fixtures can be tailored in size, shape, and clamping mechanism as per the customers drawing. Hardness levels, die heads (single/multiple), and finish types are also fully customizable to fit specific application needs.Q: When should I consider modular mounting versus base plate mounting for my application?

A: Modular mounting is ideal for setups that require flexibility or frequent reconfiguration, while base plate mounting suits fixed, permanent installations. The choice depends on your workflow and space requirements.Q: Where are these fixtures typically used?

A: Our Spot Welding Fixtures are widely utilized in the automotive industry, sheet metal fabrication, and industrial welding automation processes, particularly in assembly lines requiring robust and repeatable spot welding solutions.Q: What are the primary benefits of using anti-corrosion coated or zinc-plated finishes?

A: These finishes enhance fixture durability by protecting against rust and environmental degradation, thereby extending service life and reducing maintenance intervals, especially in demanding production environments.Q: How do I maintain Spot Welding Fixtures and what support is provided for spare parts?

A: Maintenance is straightforwardroutinely inspect for wear and replace designated wear parts as needed. We supply replaceable components to minimize downtime and keep fixtures operating efficiently.Q: What is the expected lifespan of these welding fixtures and what factors influence it?

A: With proper maintenance, our Spot Welding Fixtures can last up to 5 years. Factors such as frequency of use, material handled, and operating conditions can influence overall fixture longevity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email